Product Categories

- Products

- Cummins Engine Parts

- Cummins Engine Power Unit

- Advance Marine Gearbox

- Cummins Diesel Engine

- Cummins Diesel Generator Set

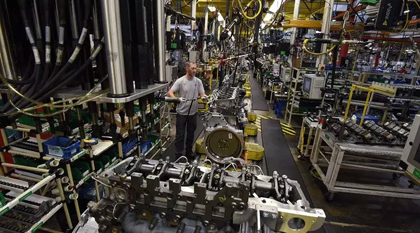

On July 26th, US local time, Cummins’ engine factory in Jamestown, New York, ushered in the second 2 million engines off the assembly line. The Jamestown Engine Plant is one of Cummins’ world’s largest production facilities, and its 2017 engine production accounted for 14.7% of Cummins’ total engine production for the year.

The Jamestown factory was built in 1974 and covers more than 1 million square feet (93,000 square meters). The factory was originally used to manufacture engine parts. Since 1981, the engine has been produced. In recent years, the annual output has exceeded 100,000 units. It is also the cradle of Cummins heavy-duty engine technology, including the current X15, ISX12, X12, ISM11 diesel and ISX12N natural gas engines, as well as the previous ISX15 diesel engine and ISX12G natural gas engine.

At present, the Jamestown factory has 1,700 employees. The company has grown by 20% since 2012 and has become one of the largest operators in the region. In the past 20 years, international trade has been the driving force for Cummins’ business growth and employment expansion. Half of Cummins’ business is outside the US, thanks to Cummins’ global influence and export capacity. Cummins local suppliers (mainly small and medium-sized The company has also achieved significant growth in its business.

The Jamestown Engine Plant is very important to Cummins, providing a wide range of engine products to application customers in different markets around the world. “From the first engine in 1981 to the innovative technology that can reduce emissions by 98% today, every engine produced at the Jamestown plant is characterized by power, reliability and durability. Representing Cummins’ strength in providing the world’s leading power solutions. Cummins will continue to invest in innovations in diesel and natural gas products, while the Jamestown plant will be for Cummins, customers and OEM partners in the future. It will remain very important for decades,” said Brett Merritt, vice president of Cummins Highway Engine Operations.

It is reported that the 2 millionth engine of the Cummins Jamestown plant will be installed on a Navistar LT series truck. At the off-line ceremony, Michael Cancelliere, president of Navistar Trucks and Components, said: “Navistar and Cummins have a long history of successful cooperation in providing services to customers, and we look forward to continuing to work with Cummins to bring customers Come to value.

The Jamestown factory, like Cummins’ facilities around the world, is committed to creating the core values of integrity, diversity, mutual support, excellence, and teamwork, and encourages employees to work together to drive the world forward and achieve a beautiful life. Anna Dibble, director of the Cummins Jamestown factory, said: “The success here is largely due to our employees who work hard every day to provide high quality products and services that meet or exceed customer expectations and work with them. We are very proud of our work. At the same time, they are committed to improving their communities and returning more than $1 million annually through charitable donations.